Environmentally Friendly Antimony-free Polyester Fiber Industrialization and Application Technologies.

The technology adopts a new type of titanium catalyst with greenenvironmental protection, hydrolysis resistance, high activity and stable efficiency to replace the traditional antimony catalyst, and realizes the industrialization and application of large-scale continuous polymerization and flexible direct spinning environmental protection polyester fiber.

Core technology:

By optimizing the synthesis scheme and addition amount of catalysts, the adaptability of antimony-free eco-environmental protection catalysts in different polymerization processes of polyester three-kettle, four-kettle and five-kettle was studied, and antimony-free catalyst micro-modification, high-proportion addition and common modified polyester engineering technology were established.

Establish the relationship between viscosity reduction and temperature, pressure and time weight in the process of antimony-free catalyzed polyester melt transportation, develop low-viscosity and high-quality antimony-free polyester melt conveying and high-power stretch spinning molding technology, and develop differentiated functional polyester filament varieties such as ecological and environmental protection semi-extinction, full extinction, cationic and so on; Establishment of antimony-free polyester fiber application technology.

Technical services :

Provide the evaluation and characterization of the environment-friendly catalyst, provide the addition technology of the environment-friendly catalyst and the optimization of the polymerization process; Provide the industrialization engineering scheme for the large-scale polymerization of the environment-friendly catalyst and the flexible direct spinning production line; Provide testing and evaluation of environmental protection characteristics of fibers and their products; And provide preparation technology and application of environment-friendly textiles.

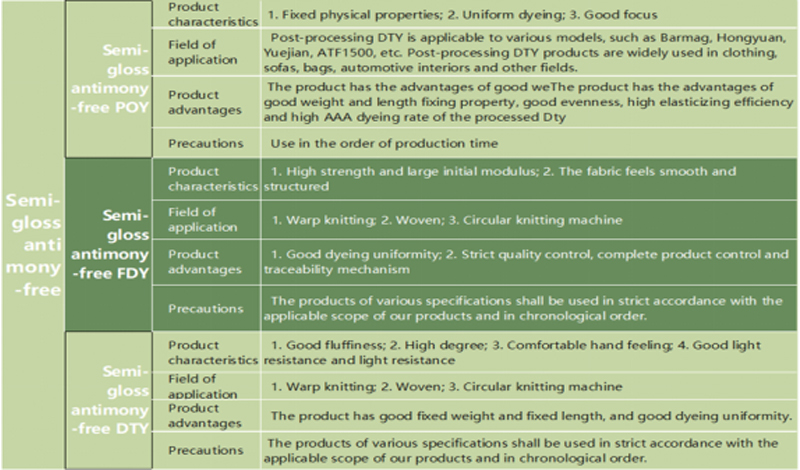

Spinnable fiber and its application field

Spinning specification:

PET POY 75D/72F 150D/144F 150D/288F;

PET FDY 75D/36F 50D/24F; P

ET DTY 75D/36F 75D/72F 150D/144F 150D/288F

Main purpose:

Environment-friendly skin-friendly clothing fabrics, shoe materials,

home textile decorative materials, bedding, carpets,

automotive interiors,

other industrial supplies, etc.

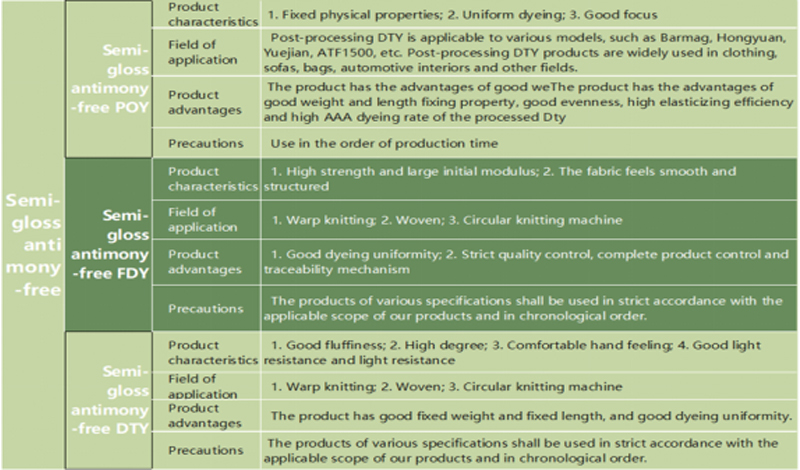

Antimony-free eco-friendly polyester product introduction

Features: No catalyst containing antimony is used in the polyester production process; environmental protection, reduce the pollution of antimony to water in the dyeing process Antimony-free chip index: viscosity 0.625

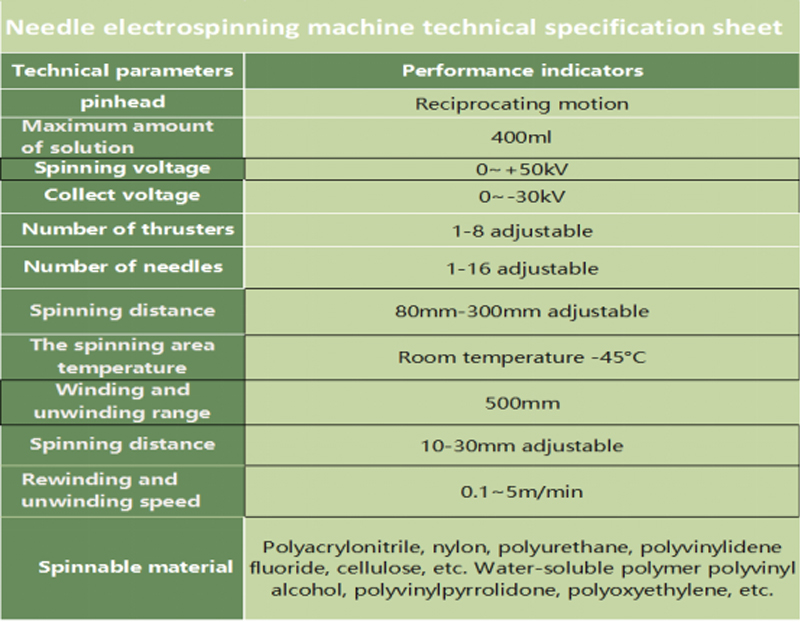

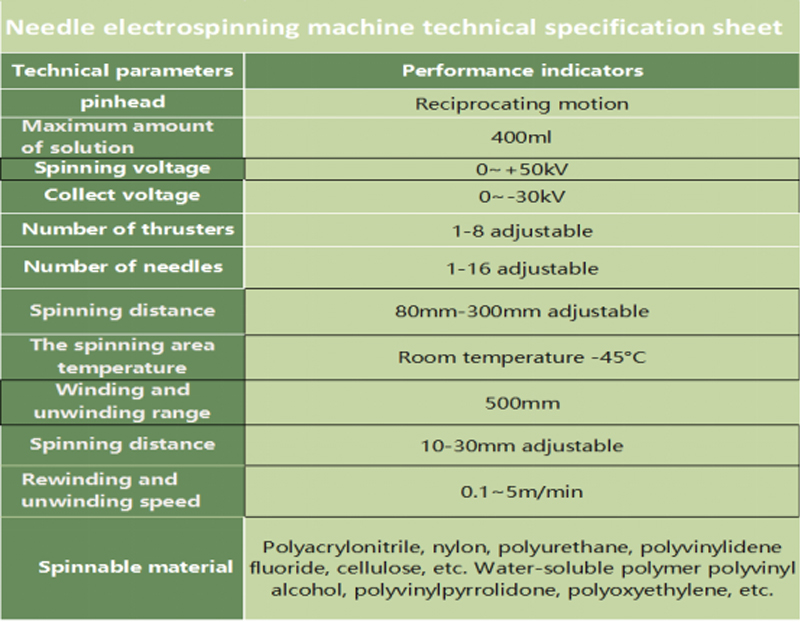

Laboratory multi- needle electrostatic spinning machine

Independent research and development of multi-needle electrospinning equipment in the laboratory can collect oriented nanofiber membranes and continuous nanofiber membranes. It can meet the needs of universities, research institutes and R & D departments of enterprises to develop and prepare

Technical characteristics of equipment

That micro-pump has a double-channel 16-needle reciprocate electrostatic spinning needle, so that the spin efficiency is higher and more uniform;

Two types of nanofiber collectors; the effective width of the roller collector is 500 mm, the diameter is 250mm, and the rotation speed of the roller is 0 — 300rpm adjustable; continuous winding and unwinding, width 500 mm, speed 0.1 ~ 5 m/min adjustable with inflatable shaft quick disassembly.

Application field of textile product

The prepared nanofiber membrane can be used in energy materials, air/liquid filtration, agriculture, biotissue engineering scaffolds, cosmetics, functional textile fabrics, building sound absorption and heat insulation, sensors, food packaging, enzyme/catalyst carriers and other fields.

Content of the Services

(1)Provide experimental machine customization, processing, commissioning, operation training and other services;

(2)Assist users in product development.

Equipment technical specifications

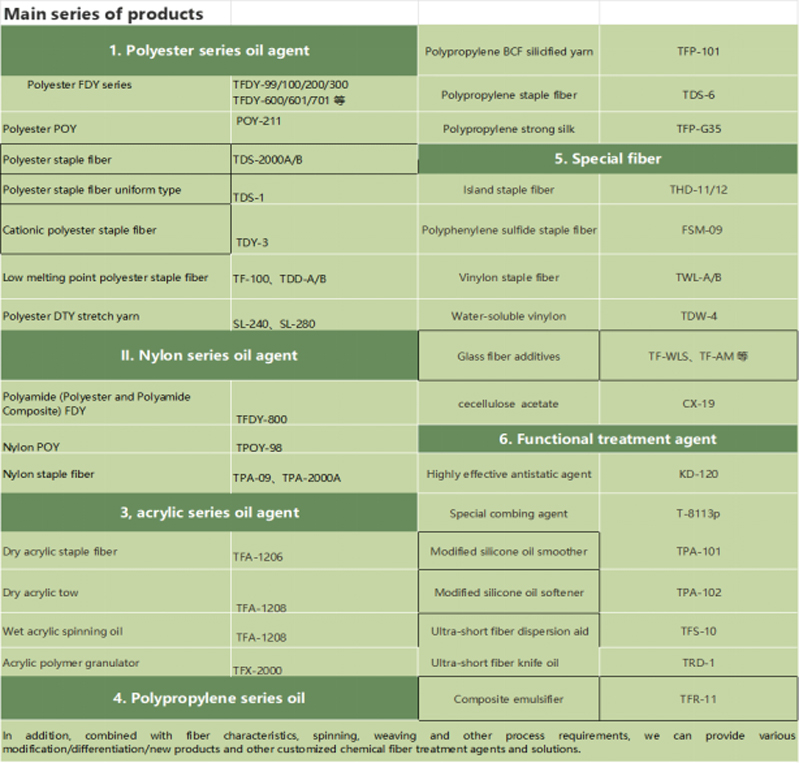

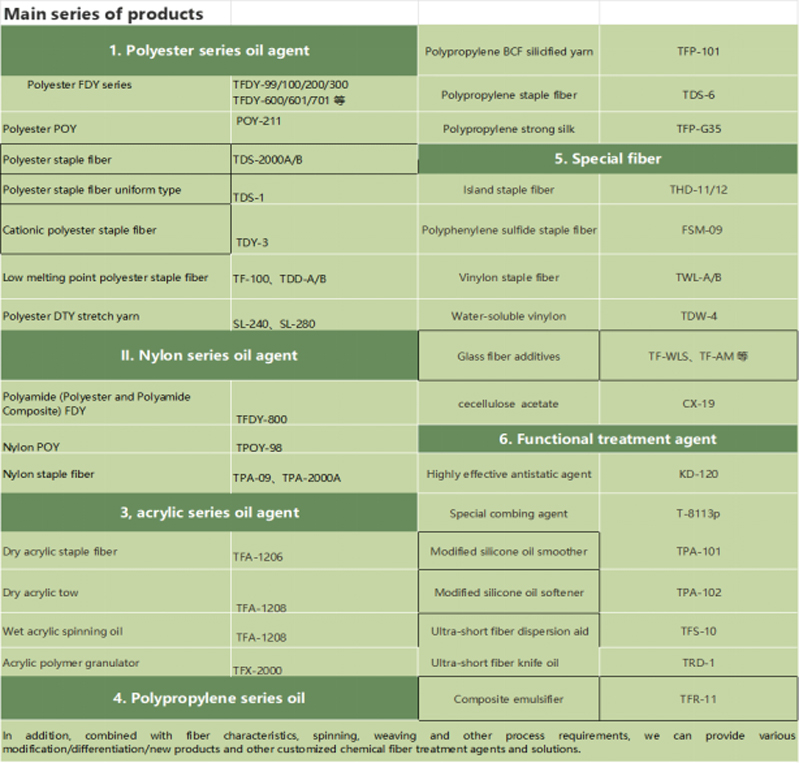

Domestic Environmental Protection Fiber Interface Treatment Agent

Environmentally Friendly Antimony-free Polyester Fiber Industrialization and Application Technologies.

The technology adopts a new type of titanium catalyst with greenenvironmental protection, hydrolysis resistance, high activity and stable efficiency to replace the traditional antimony catalyst, and realizes the industrialization and application of large-scale continuous polymerization and flexible direct spinning environmental protection polyester fiber.

Core technology:

By optimizing the synthesis scheme and addition amount of catalysts, the adaptability of antimony-free eco-environmental protection catalysts in different polymerization processes of polyester three-kettle, four-kettle and five-kettle was studied, and antimony-free catalyst micro-modification, high-proportion addition and common modified polyester engineering technology were established.

Establish the relationship between viscosity reduction and temperature, pressure and time weight in the process of antimony-free catalyzed polyester melt transportation, develop low-viscosity and high-quality antimony-free polyester melt conveying and high-power stretch spinning molding technology, and develop differentiated functional polyester filament varieties such as ecological and environmental protection semi-extinction, full extinction, cationic and so on; Establishment of antimony-free polyester fiber application technology.

Technical services :

Provide the evaluation and characterization of the environment-friendly catalyst, provide the addition technology of the environment-friendly catalyst and the optimization of the polymerization process; Provide the industrialization engineering scheme for the large-scale polymerization of the environment-friendly catalyst and the flexible direct spinning production line; Provide testing and evaluation of environmental protection characteristics of fibers and their products; And provide preparation technology and application of environment-friendly textiles.

Spinnable fiber and its application field

Spinning specification:

PET POY 75D/72F 150D/144F 150D/288F;

PET FDY 75D/36F 50D/24F; P

ET DTY 75D/36F 75D/72F 150D/144F 150D/288F

Main purpose:

Environment-friendly skin-friendly clothing fabrics, shoe materials,

home textile decorative materials, bedding, carpets,

automotive interiors,

other industrial supplies, etc.

Antimony-free eco-friendly polyester product introduction

Features: No catalyst containing antimony is used in the polyester production process; environmental protection, reduce the pollution of antimony to water in the dyeing process Antimony-free chip index: viscosity 0.625

Laboratory multi- needle electrostatic spinning machine

Independent research and development of multi-needle electrospinning equipment in the laboratory can collect oriented nanofiber membranes and continuous nanofiber membranes. It can meet the needs of universities, research institutes and R & D departments of enterprises to develop and prepare

Technical characteristics of equipment

That micro-pump has a double-channel 16-needle reciprocate electrostatic spinning needle, so that the spin efficiency is higher and more uniform;

Two types of nanofiber collectors; the effective width of the roller collector is 500 mm, the diameter is 250mm, and the rotation speed of the roller is 0 — 300rpm adjustable; continuous winding and unwinding, width 500 mm, speed 0.1 ~ 5 m/min adjustable with inflatable shaft quick disassembly.

Application field of textile product

The prepared nanofiber membrane can be used in energy materials, air/liquid filtration, agriculture, biotissue engineering scaffolds, cosmetics, functional textile fabrics, building sound absorption and heat insulation, sensors, food packaging, enzyme/catalyst carriers and other fields.

Content of the Services

(1)Provide experimental machine customization, processing, commissioning, operation training and other services;

(2)Assist users in product development.

Equipment technical specifications

Domestic Environmental Protection Fiber Interface Treatment Agent